Leveraging Predictive Analytics for Growth

Implementing and Monitoring Predictive Analytics Strategies

Implementing Predictive Maintenance Strategies

When it comes to keeping equipment running smoothly, predictive maintenance strategies offer a game-changing approach. Rather than waiting for something to break, this method focuses on spotting potential issues early. Catching problems before they escalate can save businesses thousands in repair costs and prevent unexpected downtime. Modern sensor technology plays a key role here, constantly monitoring equipment health and feeding data to advanced analysis systems.

Setting up clear performance metrics is essential for tracking how well these strategies work. Companies need to regularly check if their maintenance plans align with broader business goals and deliver solid returns. This ongoing evaluation helps fine-tune the approach for better results.

Gathering and Analyzing Data for Better Predictions

Quality predictions start with comprehensive data collection. Strategically positioned sensors capture critical operational details like vibration patterns, temperature fluctuations, and energy consumption levels. This wealth of information requires careful examination to spot unusual patterns that might signal looming equipment failures.

Today's analysis tools, powered by machine learning, can detect subtle changes that human operators might miss. These sophisticated systems process vast amounts of data to identify even minor deviations from normal operating conditions.

Building Accurate Prediction Models

Creating reliable predictive models represents a crucial phase in the process. These models learn from historical data to forecast potential equipment issues with impressive precision. Depending on the equipment and available data, different modeling approaches might be used, ranging from regression analysis to advanced machine learning techniques.

The models' effectiveness depends heavily on both the quality and volume of training data they receive. Rigorous testing ensures these models perform well in real-world scenarios, providing dependable forecasts that maintenance teams can trust.

Designing Effective Monitoring Systems

A well-planned monitoring setup forms the backbone of any predictive maintenance program. These systems must integrate smoothly with existing operations to provide a complete picture of equipment health and performance.

Effective systems don't just collect data - they alert technicians about potential problems early enough to prevent serious issues. Automated reporting features help streamline maintenance operations, saving time and reducing human error in the process.

Optimizing Maintenance Schedules

Predictive approaches revolutionize maintenance planning. Instead of following rigid schedules, companies can now base maintenance on actual equipment conditions and failure predictions. This data-driven method ensures maintenance resources get used where and when they're needed most.

Continuous Improvement Through Evaluation

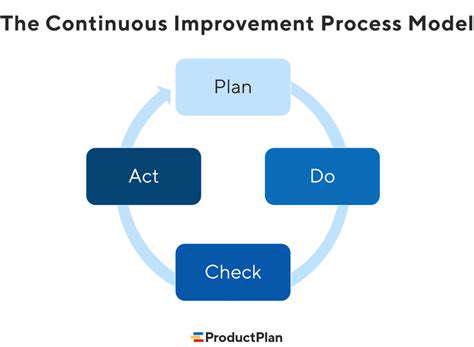

Regular performance reviews keep predictive maintenance strategies sharp. By constantly assessing how well the system works, businesses can identify improvement opportunities and adjust their approaches accordingly.

Analyzing model accuracy and operational impact reveals where the system excels and where it needs refinement. This cycle of evaluation and enhancement ensures maintenance strategies stay effective as business needs and conditions evolve.

Cultivating a Predictive Maintenance Mindset

Successfully adopting predictive maintenance requires more than just technology - it demands cultural change. Organizations need to embrace proactive thinking, value data-driven decisions, and encourage employee participation at all levels.

Investing in employee training and knowledge sharing helps maximize the benefits of this approach. When staff understand how to interpret data and respond to predictions, the entire organization operates more efficiently and profitably.

Measuring ROI and Sustaining Growth with Predictive Analytics

Establishing Meaningful ROI Metrics

The journey to measuring return on investment begins with selecting the right yardsticks. Businesses must identify key indicators that truly reflect their strategic objectives. For instance, companies focused on brand visibility might monitor social media interactions, web traffic patterns, and media coverage. Choosing relevant, quantifiable metrics makes ROI assessment far more accurate and meaningful.

Timeframes matter when evaluating returns. Short-term projects and long-term initiatives require different evaluation periods to properly assess their impact. Matching the measurement period to the project duration prevents misleading conclusions.

Thorough Financial Analysis

Accurate ROI calculation demands careful examination of all costs and revenue streams. Beyond direct expenses, companies should account for indirect costs like staff time and resource usage. Meticulous tracking of these elements reveals the true financial picture of any initiative.

Revenue attribution requires equal attention. Understanding how projects influence sales and the complete revenue cycle is crucial. This comprehensive financial scrutiny forms the foundation for trustworthy ROI figures.

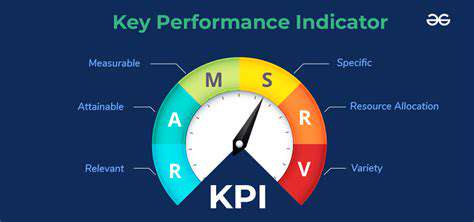

Monitoring Performance Indicators

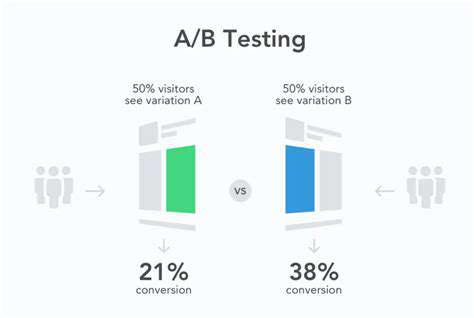

Key performance indicators serve as vital navigation tools for business growth. Regular KPI tracking helps identify trends and opportunities for strategic adjustments. Metrics like website conversion rates, customer acquisition costs, and long-term customer value provide valuable insights into business health.

Executing Data-Driven Growth Plans

With solid ROI data in hand, companies can implement targeted growth strategies. These might include refining marketing approaches, enhancing product lines, or entering new markets. The most successful implementations stem from decisions grounded in solid financial analysis and business intelligence.

Ongoing monitoring ensures these strategies continue delivering value over time. Regular reviews allow for course corrections that maintain effectiveness and efficiency.

Maintaining Growth Trajectories

Sustained business growth isn't accidental - it results from consistent effort and strategic adaptation. Regular ROI reviews, trend analysis, and strategy adjustments keep companies moving forward. This dynamic approach prevents stagnation and ensures continued relevance in changing markets.

Responding to Market Dynamics

The business environment never stands still. New technologies, shifting consumer preferences, and competitive moves all influence market conditions. Regular ROI analysis helps companies stay agile and responsive to these changes. Adaptability isn't just advantageous - it's essential for long-term business survival and success. Proactive adjustments allow firms to seize emerging opportunities while managing potential risks effectively.

Read more about Leveraging Predictive Analytics for Growth

Hot Recommendations

- Personalizing Email Content with User Behavior

- Geofencing for Event Attendance Tracking

- Reputation Management on Social Media

- UGC Beyond Photos: Videos, Testimonials, and More

- The Future of Data Privacy Regulations

- Accelerated Mobile Pages (AMP) Benefits and Implementation

- The Future of CRM: AI and Voice Integration

- Google Ads Smart Bidding Strategies: Maximize Value

- Common A/B Testing Pitfalls to Avoid

- Local SEO Strategies for Small Businesses